Customized for your business

Machine Learning Software for the 3D-Printing Industry

Quality Control

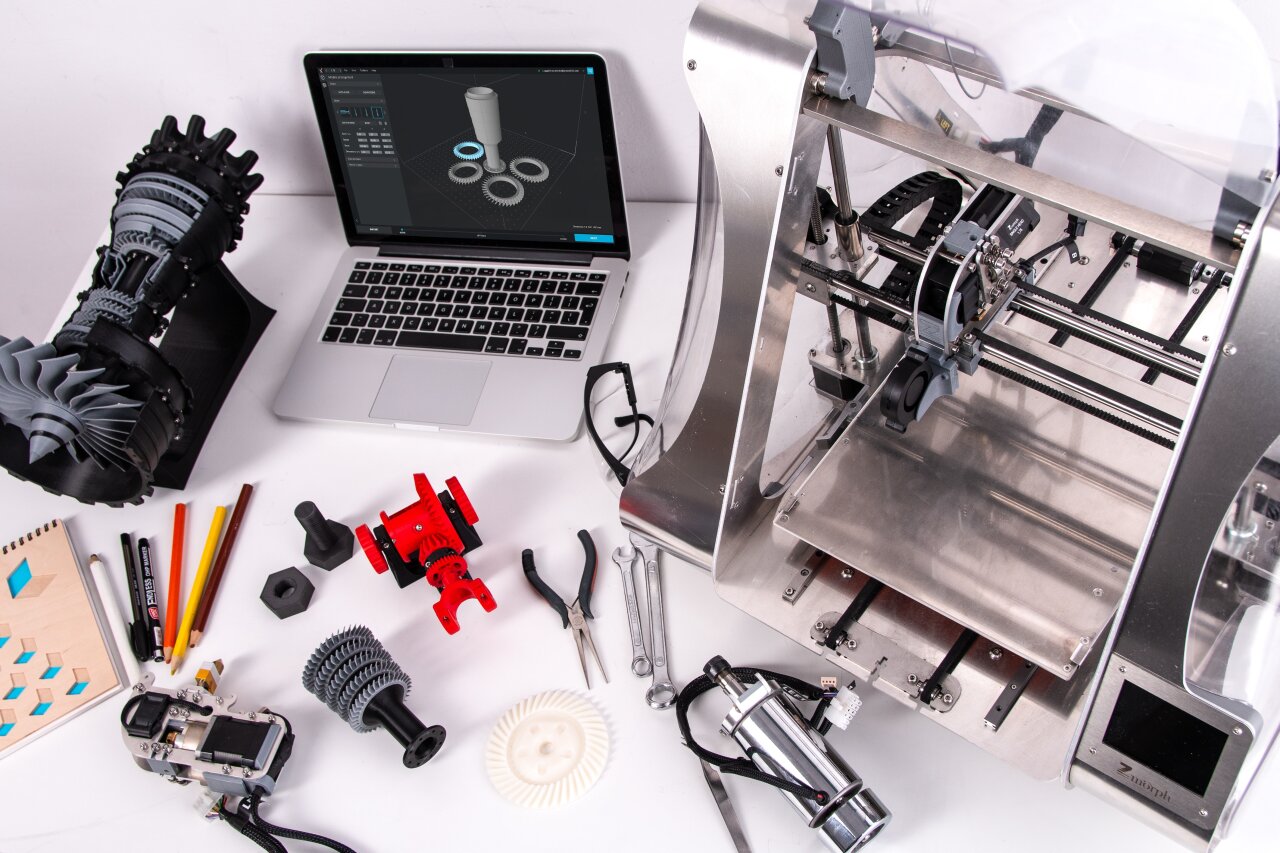

Using image recognition, Machine Learning (ML) algorithms can control product quality during the printing process. Specific requirements can hence be tested and deviations corrected while printing, improving standards and ensuring high quality. Product defects can be identified in an early stage, reducing costs and material waste.

3D Product Design

3D product design can be costly and time-consuming. With a design feature database, Machine Learning (ML) techniques can aid designers during the design process. The ML software can make recommendations to the designer, ensuring printability, reducing design mistakes, and helping to optimize material use.

Attack Detection

Machine Learning can be used to prevent cyberattacks on 3D-printing systems. Since ML algorithms can learn patterns from data, it has the ability to detect malicious attacks and to spot anomalies in the system. Real-time visualization and image classification, for instance, can be used to detect attacks on 3D printers.

FAQ

Why dida?

We are a software company specialized in Algorithms and Machine Learning (ML) and most of our 30+ employees have a scientific background in Mathematics and Physics. We follow the developments in ML research and have multiple years of experience bringing this knowledge to customers and into production.

Why a customized solution?

No Machine Learning task is alike. The data that is available and the requirements always differ and might not be captured by off-the-shelf software. From us, you get an individual solution. You own the code, the data and we integrate it into your current software environment.

What do we offer?

We offer initial proof of concepts and the complete development of production software. Due to the experience and background of our team we can as well offer larger research projects.

I am new to Machine Learning

In our Tech Lunch, we will give you 45 minutes of information on a ML topic of your choice.

I have a project idea already

In our ML Expert talk you will get 1 hour consultation & discussion about your specific use case.

Not sure? Pick the first option.

I am new to Machine Learning

I have a project idea already